Production Process Of Graphite Electrode

Graphite electrodes are a type of high-temperature resistant graphitic conductive material produced through a series of processes including kneading, forming, baking, impregnation, graphitization, and machining, with petroleum coke and needle coke as aggregates and coal tar pitch as a binder. Graphite electrodes serve as essential high-temperature conductive materials in electric arc furnace (EAF) steelmaking. They transmit electrical energy into the furnace, where the high-temperature arc generated between the electrode tip and the charge material acts as the heat source for melting the charge during steel production.

Raw Material

Petroleum Coke And Needle Coke

Crushing, Screening And Batching

Prior to batching, the calcined petroleum coke (CPC) and needle coke must undergo intermediate crushing, milling, and screening. Following this, the raw materials—including various grain sizes of aggregates, fine powders, and binders—are precisely calculated, weighed, and batched according to the formulation requirements.

Kneading

The kneading process involves uniformly mixing and blending predetermined quantities of carbonaceous aggregates (various particle sizes) and fine powders with a specified amount of coal tar pitch binder at controlled temperatures. This results in the formation of a homogeneous, plastic paste ready for subsequent molding.

Forming

The forming process involves subjecting the prepared carbonaceous paste to external forces through specialized forming equipment, inducing plastic deformation to produce green products with specified: geometry, dimensional accuracy, density, mechanical strength.

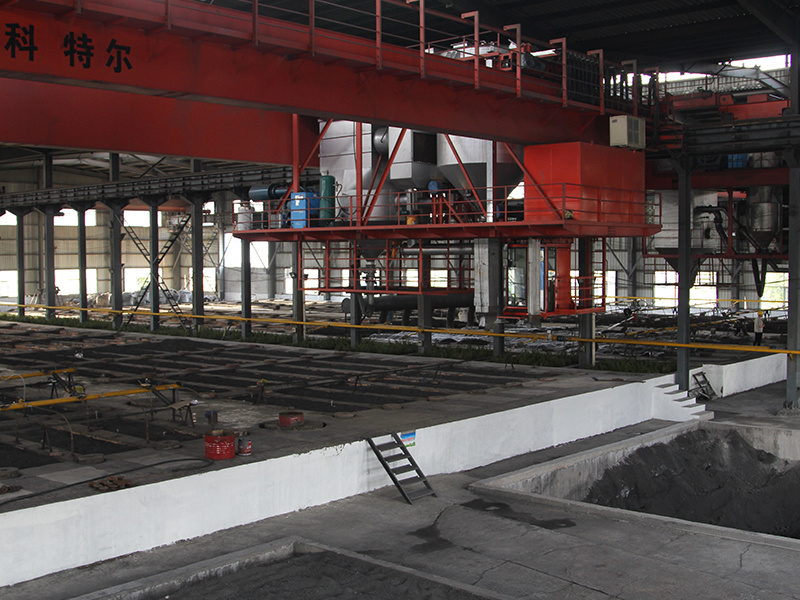

Baking

Baking is a high-temperature thermal treatment process in which carbon green products are heated in specially designed furnaces under the protection of packing materials, resulting in the carbonization of the coal tar pitch binder within the green products. Post-baking, the carbon products exhibit: enhanced mechanical strength, reduced electrical resistivity, improved thermal stability and superior chemical stability

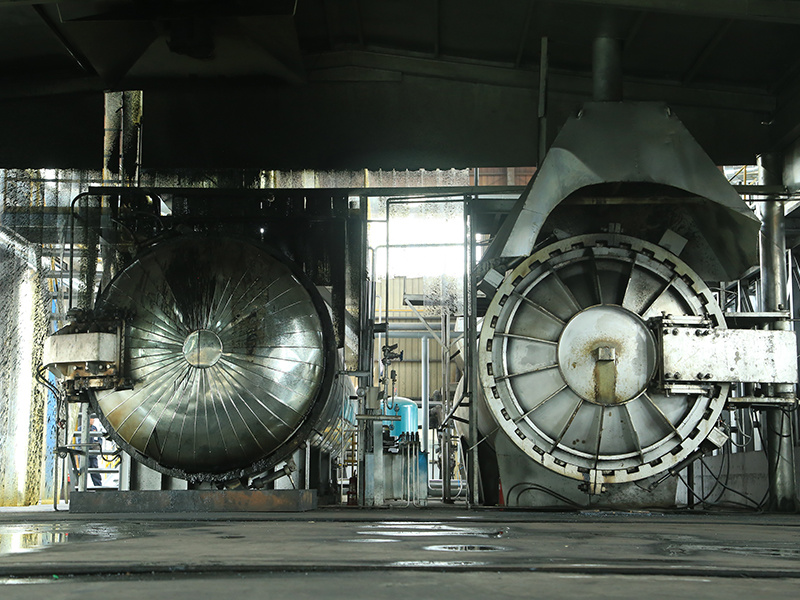

Impregnation (With Impregnating Pitch)

Impregnation is a specialized treatment in which carbon materials are placed in a pressure vessel, where liquid impregnating pitch is forced into the pores of electrode products under controlled temperature and pressure conditions. Key Objectives: reduced porosity of the final product, increased bulk density and mechanical strength and enhanced electrical and thermal conductivity

Secondary Baking

Electrodes requiring higher bulk density (all grades except RP) and joint blanks (nipple stock) must undergo secondary baking. Joint blanks further require triple impregnation & quadruple baking or double impregnation & triple baking processes.

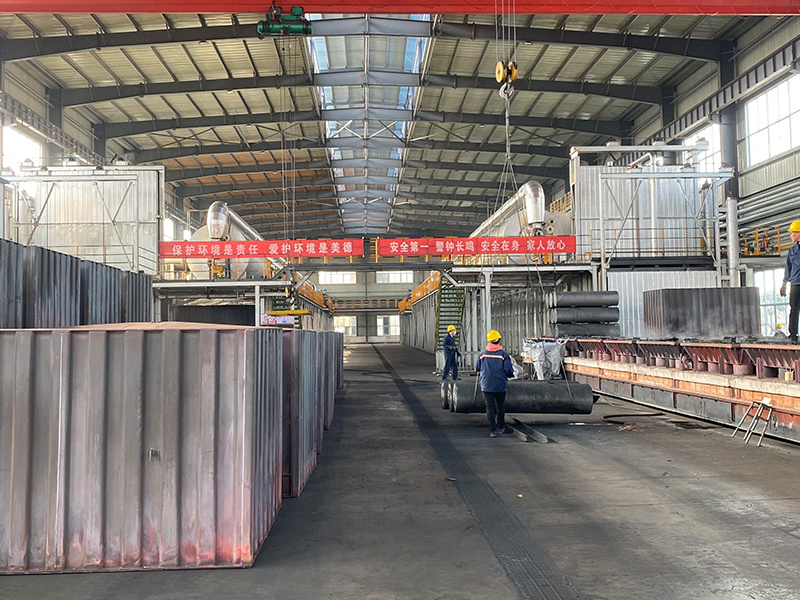

Graphitization

The graphitization process enhances product performance by: Improving electrical and thermal conductivity; Increasing impact resistance and chemical stability; Developing lubricating properties and wear resistance; Removing impurities to achieve higher purity levels. For RP electrodes, the required graphitization temperature range is 2500-2600°C, with a resistivity of 8.5 μΩ·m or lower; For HP electrodes, the required graphitization temperature range is 2600-2800°C, with a resistivity of 6.0 μΩ·m or lower; For UHP electrodes, the required graphitization temperature range is above 2800°C, with a resistivity of 5.8 μΩ·m or lower.

Quality Inspection

All graphitized electrodes and joints undergo mandatory sampling and laboratory testing for testing of resistivity, flexural strength, elastic modulus, bulk density, and coefficient of thermal expansion (CTE) to verify compliance with international quality standards.

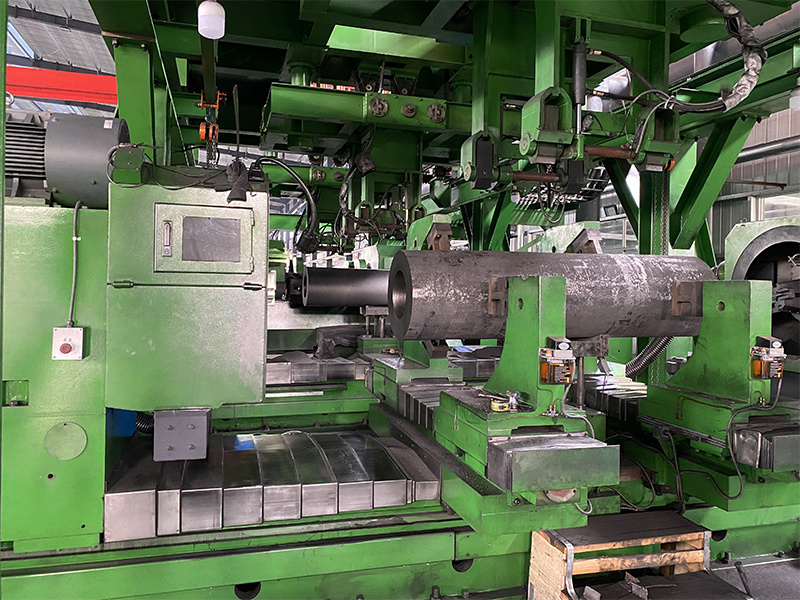

Machining

Precision machining is performed to achieve required dimensional specifications, geometric tolerances, and surface finish quality for both electrode bodies and connecting joints through controlled material removal processes.

Finished Product & Packaging Inspection

All finished electrodes undergo comprehensive quality verification including: appearance, weight, length, diameter, resistivity, bulk density, etc.; as for packaging inspection, it involves verifying the correctness of small labels, shipping marks (or marks and numbers) in compliance with customer requirements, as well as checking the sturdiness of the packaging frames, etc.